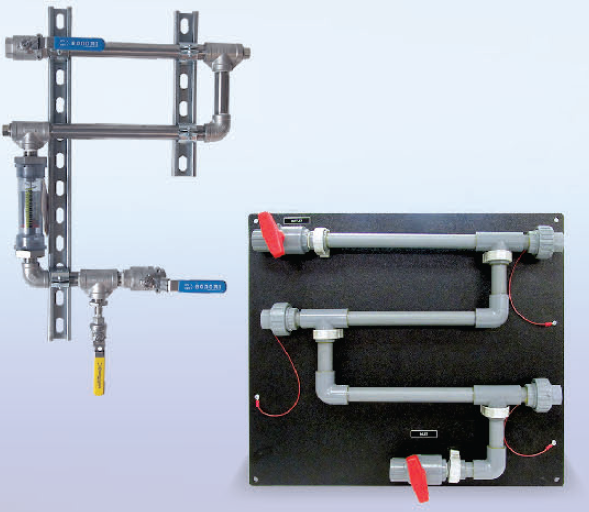

J.L. Wingert Manufactured Products

For over 58 years J.L. Wingert Co. has manufactured in Southern California with the goal of providing quality products to the water, wastewater, and process water treatment industries. Manufactured in Garden Grove, California, we pride ourselves with the quality of our “Made in the USA” products. We look forward to serving you soon!